Proceca Engineers is committed to delivering excellence in design and

engineering, ensuring your project's success from concept to

completion. Trust us to provide the expertise and meticulous attention

to detail required for your engineering needs.

At Proceca Engineers, we offer comprehensive Design and Engineering

services to meet your project's needs. Our expert team is dedicated to

ensuring the successful execution of your engineering projects by

providing a wide range of services, including:

• Designing of Control Automation Philosophy.

• Prepare Functional Design Specifications.

• Control Panel Engineering including General Arrangement, wiring &

loop drawings.

• Logic programming on all Platforms.

• Integration of I/O’s, Intelligent Devices & networks like

Controlnet, Ethernet, Device net, RIO, Modbus, Profibus etc.

• SCADA / MMI development using RS View, Wonder ware Intouch,

Intellution Fix 32 etc.

• Development of applications on Operator Interfaces.

• Integration of AC / DC, Servo Drives with PLC on various

communication protocols.

• Installation & Commissioning of Control Automation Systems.

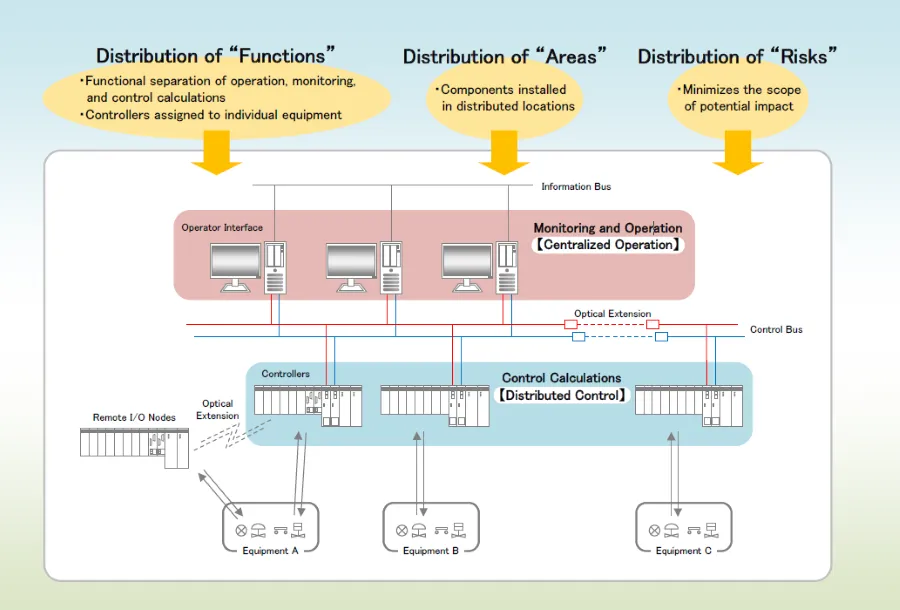

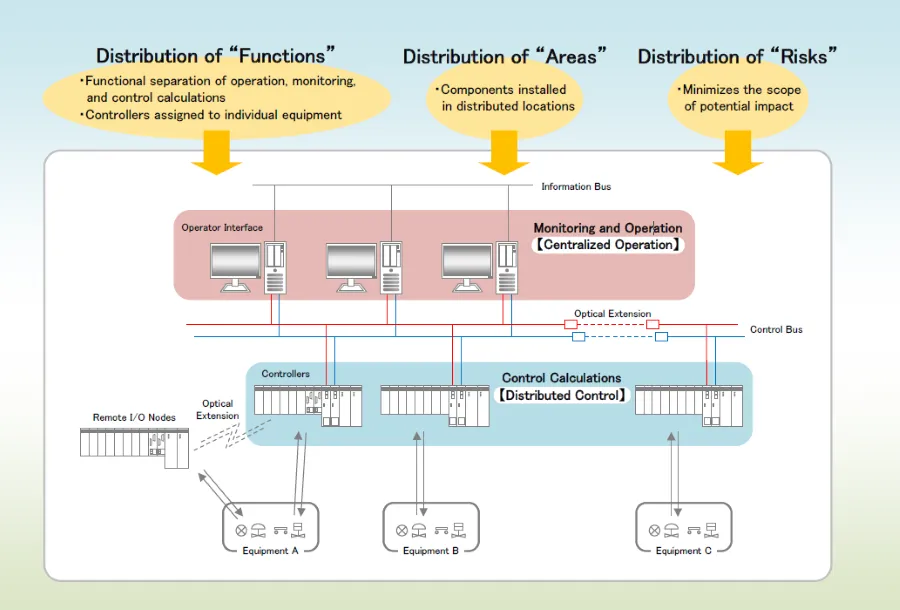

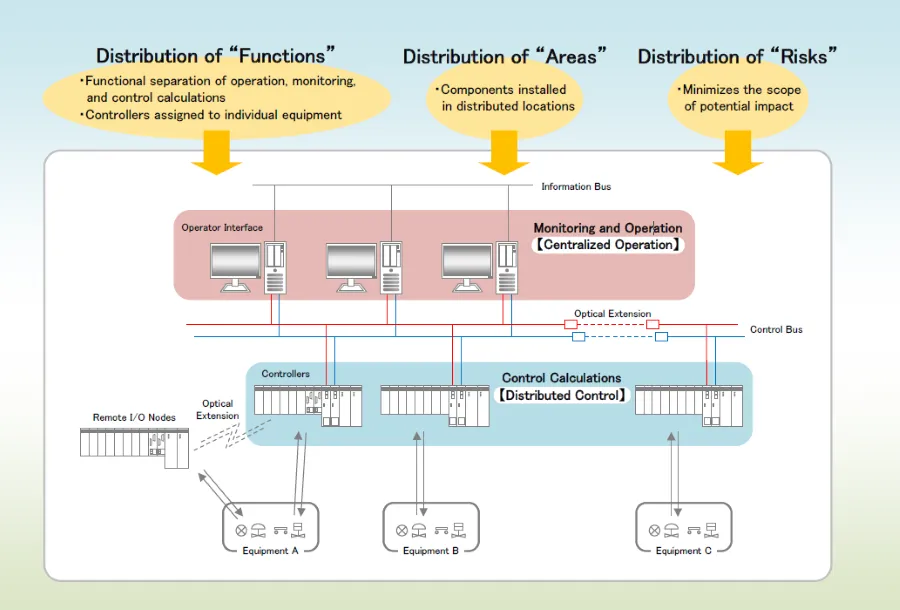

A Distributed Control System (DCS) is an automated control solution widely used in industrial plant operations. In the instrumentation industry, it’s commonly known as a DCS. Unlike centralized systems, a DCS decentralizes control by assigning controllers to individual pieces of equipment. This approach enhances system reliability and allows for efficient, long-term operation of large-scale plants, while also reducing labor requirements and improving operational efficiency.

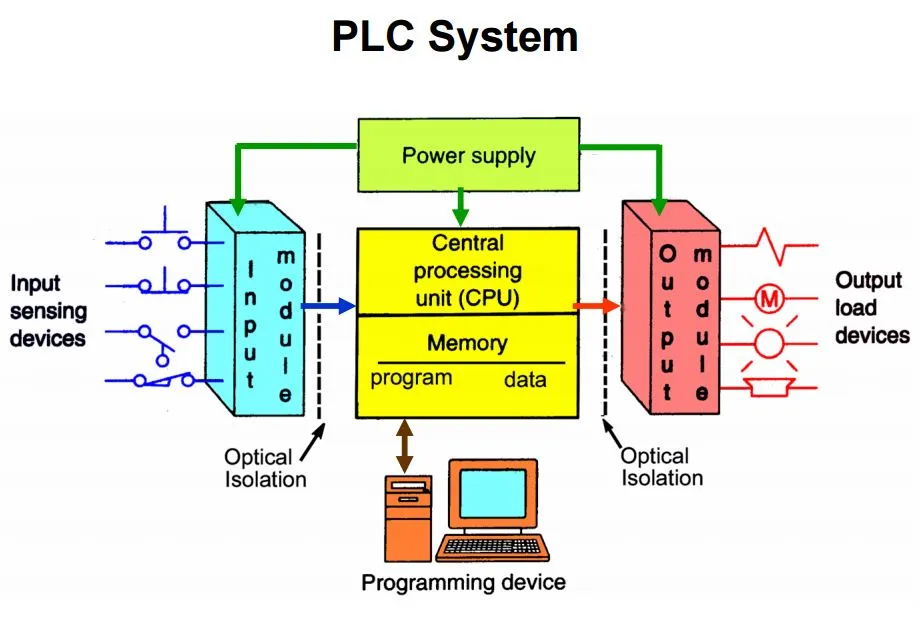

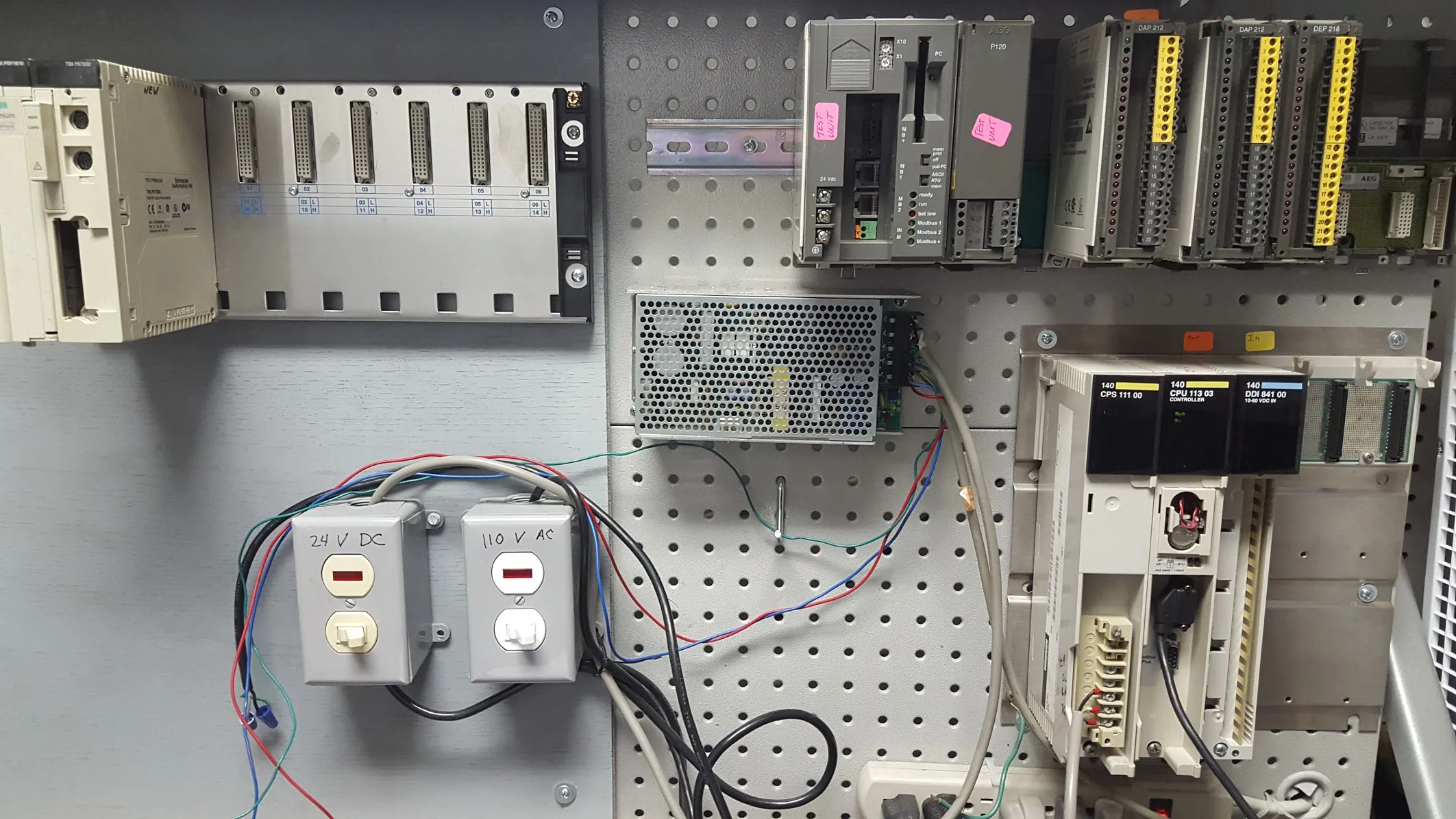

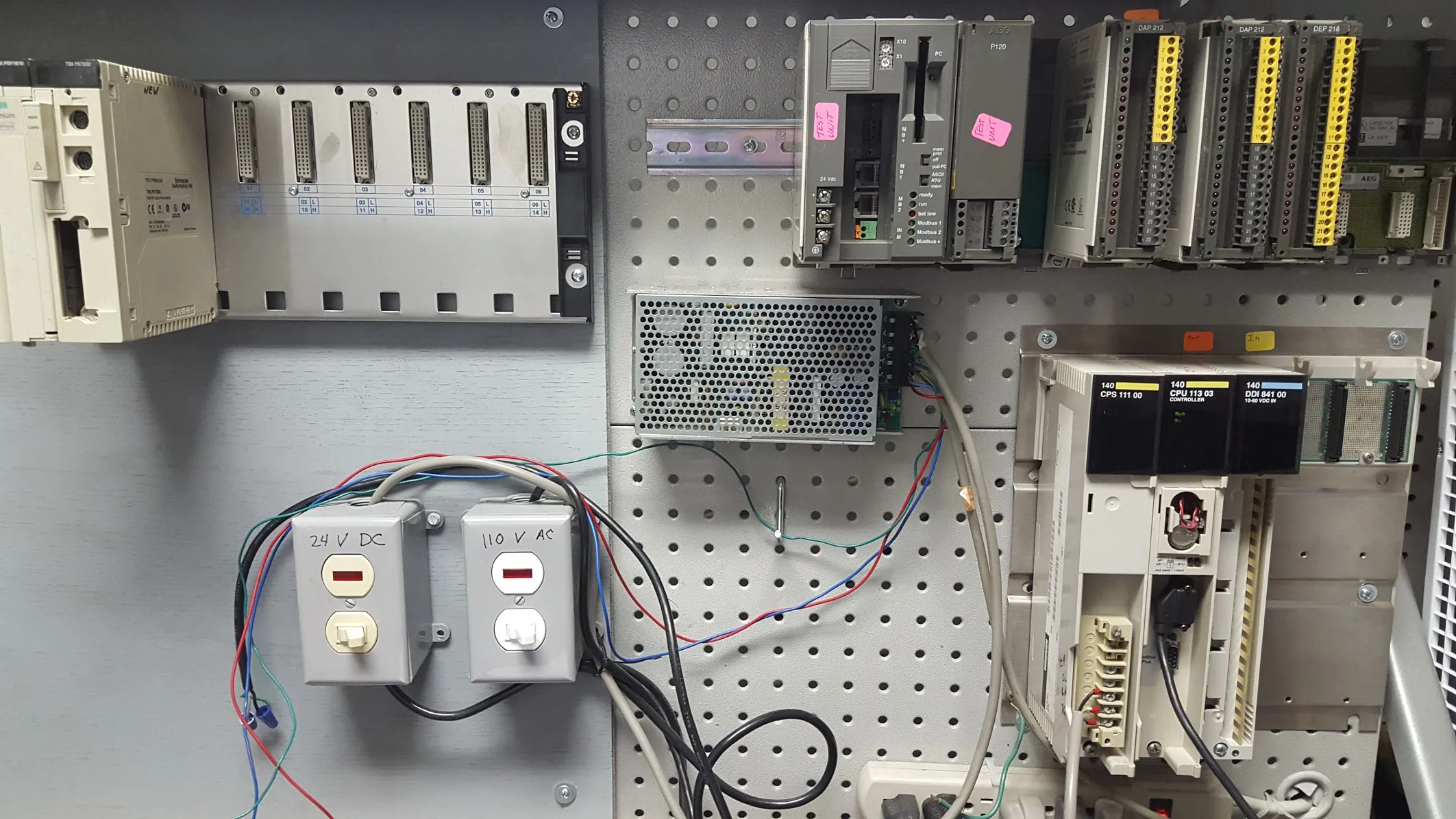

A Programmable Logic Controller (PLC) is designed for high-speed discrete logic processing, offering significantly shorter cycle times to scan I/O points and execute control operations. Originating as a replacement for hard-wired relay logic panels, PLCs are well-suited for applications where processing speed is critical. Their efficiency in handling rapid logic decisions makes them ideal for discrete manufacturing, packaging, and machinery automation, where fast response and reliability are essential.

SCADA systems originated by serving applications that require broad geographical area coverage, the concept evolved with the inception of PC-based HMIs, which replaced more expensive minicomputers in the 1980s. Instead of a wide area network that interfaces with remote terminal units (RTUs) at locations such as pump stations, a typical in-plant SCADA system uses Ethernet for communication between the HMI and PLCs. In the latter category, the SCADA system architecture shares many similarities with DCS architecture. In the former category, a SCADA system can connect corporate operations with multiple plants, each of which uses a DCS. Process manufacturers can use these enterprise-wide systems for data communications without facing geographical restrictions.

Request a quote today and let us help you embark on a transformative journey towards enhanced performance and growth.

Call Us

+91 9422006606

Email Us

datta.kawade@proceca.com